Water treatment is a crucial process in the chemical industry to ensure that the water used in various applications meets specific quality standards. Untreated water may contain contaminants that can damage industrial equipment and disrupt production processes. Therefore, the use of water treatment chemicals is the primary solution to address these issues. As a trusted chemical distributor, Nanyang Chemical provides various water treatment solutions tailored to industrial needs.

What Is Water Treatment in the Chemical Industry?

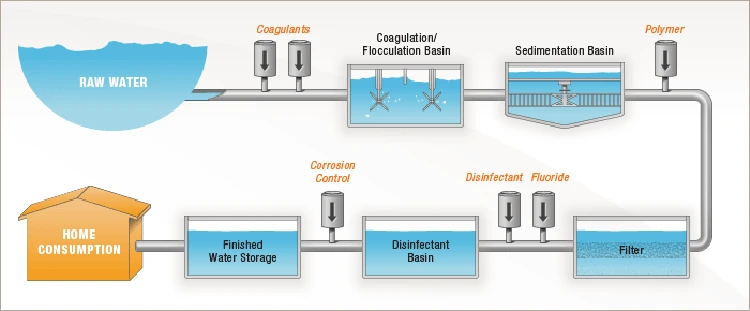

Water treatment refers to the process of treating water to improve its quality for specific uses, such as in production, cleaning, or wastewater disposal. In industrial water treatment, methods such as filtration, coagulation, flocculation, and disinfection are used to remove impurities, heavy metals, and harmful microorganisms.

Types of Water Treatment

a. Wastewater Treatment

Wastewater treatment aims to reduce pollutants in water before it is discharged into the environment or reused. Wastewater treatment in the chemical industry often involves biological, physical, and chemical processes to remove contaminants such as oils, heavy metals, and organic compounds.

b. Water Purification

Water purification is used to enhance water quality, making it suitable for industrial or human consumption. Techniques such as reverse osmosis, distillation, and activated carbon filtration are commonly used to remove impurities and harmful substances from water.

Key Processes in Water Treatment

a. Coagulation and Flocculation

This process helps remove suspended particles by adding chemicals that cause these particles to clump together and settle. Coagulation and flocculation are widely used in wastewater treatment and industrial water purification.

b. pH Adjustment in Water Treatment

Balancing the water’s pH is essential in industries because an imbalanced pH can cause equipment corrosion and affect the efficiency of chemical processes. pH adjustment in water treatment is typically achieved by adding acids or bases to regulate pH levels.

c. Chemical Dosing System

A chemical dosing system is used to precisely add the required amount of chemicals into the water to ensure the effectiveness of the treatment process. This system is commonly utilized in disinfection, coagulation, and pH control processes.

Chemicals Used in Water Treatment

a. Poly Aluminum Chloride (PAC)

Poly Aluminum Chloride (PAC) is a highly effective coagulant used in coagulation and flocculation processes. PAC is superior to other coagulants as it operates under various pH conditions and produces less sludge.

b. Sodium Hypochlorite (NaClO)

Sodium hypochlorite (NaClO) is a commonly used disinfectant in water treatment. NaClO effectively kills bacteria, viruses, and other microorganisms, making it widely used in the food, pharmaceutical, and manufacturing industries.

Benefits of Water Treatment in the Chemical Industry

- Reduces the environmental impact of industrial wastewater.

- Enhances production efficiency.

- Prevents equipment damage due to corrosion and mineral deposits.

- Ensures compliance with environmental regulations and workplace safety standards.

Conclusion

Water treatment is an essential part of the chemical industry, aiming to maintain water quality and reduce environmental impact. trusted chemical supplier ready to support your water treatment needs with top-quality solutions.