Water treatment plays a crucial role in industrial processes, ensuring water quality meets safety and environmental standards. Industries that rely on water, such as manufacturing, food processing, and pharmaceuticals, require efficient treatment methods to maintain operational efficiency and sustainability. Nanyang Chemical, a trusted supplier of industrial chemicals, provides high-quality solutions to enhance water treatment effectiveness.

Water contamination can result in equipment damage, regulatory violations, and health hazards. Effective water treatment helps industries meet environmental compliance, reduce operational costs, and enhance product quality. By utilizing the right chemicals and treatment processes, companies can achieve better efficiency and sustainability.

How Water Treatment Works

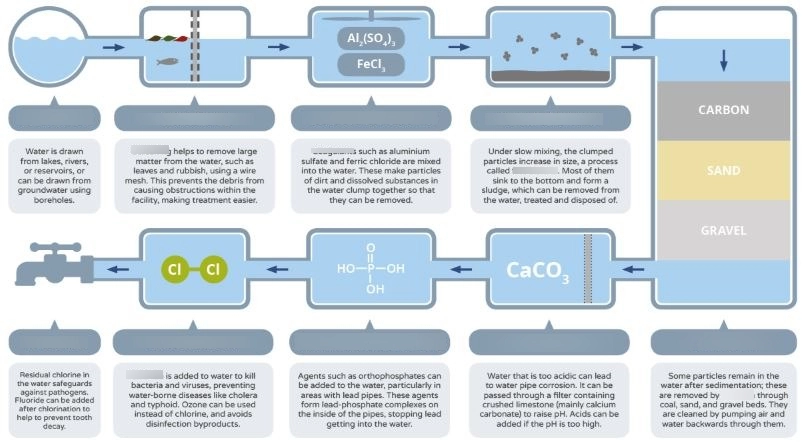

Water treatment involves several stages to remove contaminants and improve water quality. The process ensures that water is safe for industrial use and complies with environmental regulations. Below are the main steps involved:

1. Pre-Treatment

The first step in water treatment is the removal of large debris, sediments, and suspended solids. This is achieved through screening and filtration, which helps prevent clogging and damage to downstream equipment. Proper pretreatment reduces the load on subsequent treatment steps and enhances efficiency.

2. Coagulation & Flocculation

Coagulation and flocculation are essential for removing fine particles from water. Poly Aluminium Chloride (PAC) and PAM Polyacrylamide (PAM) are commonly used in this process. Coagulants help neutralize charges on particles, allowing them to clump together and form larger aggregates (flocs) that can be easily removed through sedimentation or filtration.

3. pH Neutralization & Precipitation

Maintaining the right pH level is crucial for effective water treatment. Caustic Soda Flakes—liquid and soda ash dense are used to adjust pH and facilitate the precipitation of dissolved impurities. This step ensures that contaminants such as heavy metals and dissolved solids are removed efficiently, improving water quality for industrial use.

4. Disinfection & Oxidation

Disinfection is necessary to eliminate bacteria, viruses, and other harmful microorganisms from water. TCCA Trichloroisocyanuric Acid Granular is an effective disinfectant that ensures water safety. Oxidation processes also help break down organic pollutants and remove undesirable odors and colors, making the treated water suitable for industrial applications.

5. Heavy Metal Removal & Scaling Control

Industrial water often contains dissolved heavy metals that need to be removed to prevent contamination and equipment damage. EDTA (EthylenediamineTetraacetic Acid Disodium Salt) and Sodium Dihydrogen Phosphate effectively bind and remove metal ions from water. Additionally, these chemicals help prevent scaling in pipes and equipment, ensuring smooth operations.

6. Final Filtration & Polishing

The last step in water treatment involves final filtration and polishing to remove any remaining impurities. Monohydrate Citric Acid is used in this process to enhance water clarity and purity. This step ensures that treated water meets industrial standards and is safe for reuse or discharge.

Key Water Treatment Methods in Industries

Different industries require specialized water treatment methods to meet their specific needs. The most common methods include:

- Coagulation & Flocculation: Used to remove suspended solids, organic matter, and turbidity from water.

- Neutralization & Precipitation: Essential for pH balance and the removal of dissolved contaminants, such as heavy metals.

- Disinfection & Sterilization: Ensures microbial safety for industrial and potable water use.

- Filtration & Polishing: Provides the final refinement of water quality before use or discharge.

These methods help industries optimize water usage, reduce waste, and maintain regulatory compliance, ultimately contributing to cost savings and environmental protection.

Applications of Water Treatment in Various Industries

Water treatment is widely used across multiple industries to ensure safe and efficient operations. Key applications include:

- Manufacturing: Industrial processes require clean water to prevent equipment corrosion and contamination. Proper water treatment enhances product quality and extends the lifespan of machinery.

- Food & Beverage Industry: Ensuring clean water is critical for food safety and compliance with health regulations. Treated water is used in production, cleaning, and cooling systems.

- Pharmaceutical & Textile Industry: High-quality water is necessary to meet strict manufacturing standards and avoid contamination. Water treatment helps remove impurities and maintain consistency in production processes.

Advantages of Using Chemicals in Water Treatment

Water treatment chemicals play a vital role in ensuring process efficiency and environmental sustainability. The key benefits include:

- Cost Efficiency & Process Optimization: Reduces operational costs while maximizing treatment performance.

- Reduced Waste & Environmental Impact: Proper chemical treatment minimizes industrial waste and prevents pollution.

- Improved Water Quality Compliance: Ensures adherence to local and international water quality regulations.

Using the right combination of water treatment chemicals improves overall plant performance and protects valuable assets from damage.

Tips for Choosing the Right Water Treatment Chemicals

Selecting the right water treatment chemicals is essential for achieving optimal results. Important factors to consider include:

- Product Quality & Purity: High-grade chemicals ensure effective treatment and prevent unwanted side effects.

- Compliance with Industry Standards & Certifications: Choosing chemicals that meet regulatory requirements guarantees safe and legal operations.

- Reliable Supplier & Technical Support: Working with a trusted supplier like Nanyang Chemical provides access to premium solutions and expert guidance in water treatment.

Conclusion

Water treatment is an essential process for various industries, ensuring clean and safe water for operational efficiency. The use of high-quality chemicals like Poly Aluminium Chloride (PAC), Caustic Soda, PAM, and TCCA significantly improves treatment effectiveness. Choosing a trusted supplier like Nanyang Chemical ensures superior quality and compliance with industry standards.

Frequently Asked Questions (FAQ)

For premium water treatment solutions, consult Nanyang Chemical, your trusted partner in industrial water treatment chemicals.